Epoxy Resin Market Size Expected to Hit USD 20.31 Bn by 2034

According to Precedence Research, the global epoxy resin market size is expected to hit approximately USD 20.31 billion by 2034, increasing from USD 12.33 billion in 2025, fueled by strong demand in construction, automotive, and electronics industries. Between 2025 and 2034, the industry is growing at a annual rate of 5.71%.

Ottawa, Aug. 14, 2025 (GLOBE NEWSWIRE) -- In terms of revenue, the epoxy resin market was valued at USD 11.58 billion in 2024 and is expected to grow from USD 12.33 billion in 2025 to USD 20.31 billion by 2034.

In terms of CAGR, the market is poised to grow at a compound annual growth rate (CAGR) of 5.71% from 2025 to 2034. The epoxy resin market is driven by rising demand in construction, automotive, electronics, and wind energy applications for high-performance, durable, and chemical-resistant materials.

Note: This report is readily available for immediate delivery. We can review it with you in a meeting to ensure data reliability and quality for decision-making.

Try Before You Buy – Get the Sample Report@ https://www.precedenceresearch.com/sample/2150

Epoxy Resin Market – What You Need to Know:

- 2024 Market Size: USD 11.58 Billion

- 2025 Market Size: USD 12.33 Billion

- 2030 Market Size: USD 27.51 Billion

- 2032 Market Size: USD 16.65 Billion

- 2034 Market Size: USD 18.48 Billion

- CAGR (2025-2034): 5.71%

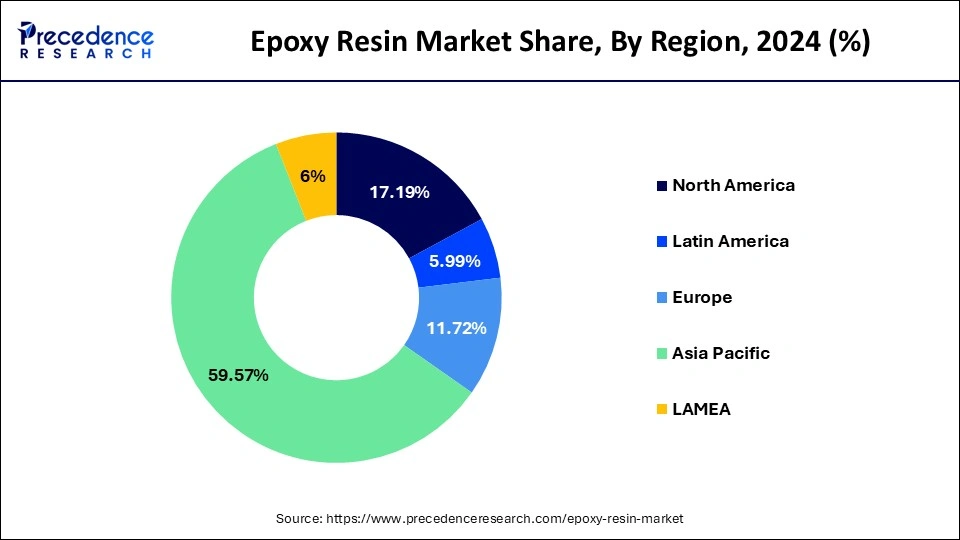

- Largest Regional Market Share in 2024: Asia Pacific.

- Asia Pacific accounted for the largest market share of 59.57% in 2024.

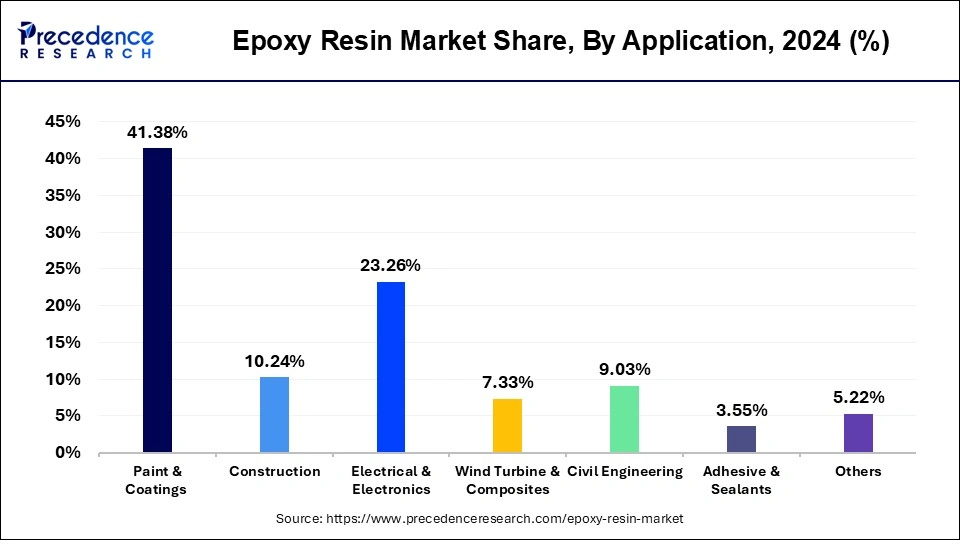

- By application, the paints and coatings segment contributed the highest market share of 41.38% in 2024.

- By application, the adhesives and sealants epoxy resin segment is expanding at a CAGR of 5.60% from 2025 to 2034.

- By raw material, the DGBEA (Bisphenol A and ECH) segment held the major market share of 36.15% in 2024.

- By technology, the solvent cut epoxy segment captured the biggest revenue share of 29.87% in 2024.

- By sales channel, the direct company sale segment is estimated to hold the highest market share of 32.25% in 2024.

- By end use, the consumer goods (including sporting equipment) segment generated over 46.93% of revenue share in 2024.

Global Epoxy Resin Market Size Analysis, By Segments 2022 to 2024

Epoxy Resin Market Size (USD Million) By Sales Channel 2022-2024

| By Sales Channel | 2022 | 2023 | 2024 |

| Direct Company Sale | 3,295.4 | 3,508.9 | 3,733.1 |

| Direct Import | 1,520.2 | 1,623.5 | 1,732.5 |

| Distributors & Traders | 3,010.4 | 3,221.4 | 3,444.4 |

| Retailers | 2,353.0 | 2,506.1 | 2,667.1 |

Epoxy Resin Market Size (USD Million) By Technology 2022-2024

| By Technology | 2022 | 2023 | 2024 |

| Solvent Cut Epoxy | 3,028.0 | 3,237.1 | 3,457.7 |

| Liquid Epoxy | 2,469.7 | 2,637.6 | 2,814.5 |

| Waterborne Epoxy | 2,150.7 | 2,287.7 | 2,431.4 |

| Others | 2,530.6 | 2,697.7 | 2,873.4 |

Order Now for Instant Digital Delivery of the Complete Study ➡️ https://www.precedenceresearch.com/checkout/2150

Market Overview: What is an Epoxy Resin?

Epoxy resin is a thermosetting resin, valued for its high adhesive power and chemical resistance as well and mechanical durability of the material. Due to the highly cross-linked structure produced through reaction with epoxide monomers and curing agents such as amines, anhydrides, or phenols. Its high bonding strength, thermal resistance to corrosion, electrical insulation, and industry have been reported in construction, automobile, aerospace, electronics, and coatings fields on a large scale.

Also, the applications of epoxy resin in advanced composites, protective coatings, and encapsulating electronic components support the position of epoxy resin in the market.

Latest Trends in the Epoxy Resin Market

- Growth of Bio-based and Waterborne Epoxies: Rising environmental awareness is driving demand for sustainable, low-VOC epoxy formulations made from renewable sources.

- Emergence of Smart & Self-Healing Coatings: Advanced epoxy systems now feature self-repair capabilities, improving durability in sectors like automotive and aerospace.

- Integration into 3D Printing & Additive Manufacturing: Epoxies are being engineered for high-resolution printing and complex additive manufacturing processes.

- Advanced Cure Monitoring Technologies: Innovations in real-time cure control are enhancing strength, consistency, and quality in epoxy-based composites.

- Rising Demand in Wind Energy, Automotive & Aerospace: Lightweight, high-performance epoxy composites are increasingly used in wind turbine blades, vehicle parts, and aircraft structures.

- Shift Toward Liquid Epoxy Formulations: Liquid resins offer greater versatility for complex molds, coatings, and applications requiring detailed processing.

-

Increased Focus on Safety & Regulation Compliance: Stricter workplace and environmental regulations are encouraging the development of safer, more compliant epoxy products.

Epoxy Resin Market Opportunity:

Rising Demand for Bio-based Polyepoxides

The opportunity in the epoxy resin market is the increasing presence of demand for bio-based polyepoxides due to the increasing environmental concerns and resins' dependency on petroleum products. Certain bio-based epoxies come in renewable form, matching the performance of conventional epoxy resins used in a variety of materials, including paints, adhesives, composite materials, and encapsulations.

Bio-based solutions complement the overall green agenda and also entail new prospects of growth since manufacturers need to serve new demand within industries targeting the production of low-carbon and non-toxic material solutions.

Case Study: Real-Time Cure Monitoring via Carbon Nanotube Networks

A groundbreaking study demonstrates how embedding single-walled carbon nanotubes (SWCNTs) within epoxy resin systems enables real-time monitoring of the curing process—without impairing resin performance. Researchers set up two curing programs to assess mechanical enhancements:

- Program A: Standard high-temperature curing.

- Program B: High-temperature curing followed by an extended post-cure at 100 °C for 24 hours.

By correlating changes in electrical resistance through the embedded SWCNT network with curing stages, the researchers discovered that adding a 24-hour post-cure increased tensile strength by 60% and elongation by 164% compared to industry‑standard cycles.

Why It Matters

- Non-destructive inspection: The electrical resistance measurement offers a scalable, real-time alternative to traditional methods (e.g., differential scanning calorimetry) for assessing cure state.

- Performance optimization: Significant enhancements in mechanical properties make these epoxy systems especially attractive for aerospace and automotive composites, where material strength and reliability are paramount.

-

Market relevance: This aligns with your focus on epoxy resin applications in high-performance sectors and supports trends toward innovation and process efficiency in the epoxy resin market landscape.

Quick Summary

| Feature | Details |

| Technique | SWCNT-embedded epoxy resin for real-time cure monitoring |

| Mechanical Gains | +60% tensile strength, +164% elongation with extended post-cure |

| Industry Applications | Aerospace, automotive, high-performance composites |

| Market Implication | Enables precision, performance, and scalable quality control |

Stay ahead of industry shifts—secure your copy of the full market report today@ https://www.precedenceresearch.com/sample/2150

Key Challenges in the Epoxy Resin Market:

Volatility of Raw Materials

Volatility of raw material pricing, especially bisphenol A (BPA) and epichlorohydrin (ECH), which are petroleum byproducts, is one of the prime constraints facing the market. Also, there are strict controls over volatile organic compounds (VOCs), which means that manufacturers must observe high-quality products and ensure environmental compliance.

Meeting such standards may require an investment in a skilled workforce, new technologies, and sustainable processes of production, thus raising the costs of operation. These factors, including raw material price fluctuations and costs associated with compliance, have been a major threat to the growth of the market.

Epoxy Resin Market Key Regional Analysis:

| Regions | Countries Covered |

| Asia-Pacific | China, Japan, India, South Korea, Australia, Rest of Asia-Pacific |

| North America | U.S., Canada, Mexico |

| Europe | Germany, U.K., France, Italy, Spain, Rest of Europe |

| Latin America | Brazil, Argentina, Rest of Latin America |

| Middle East & Africa | GCC, South Africa, Rest of Middle East & Africa |

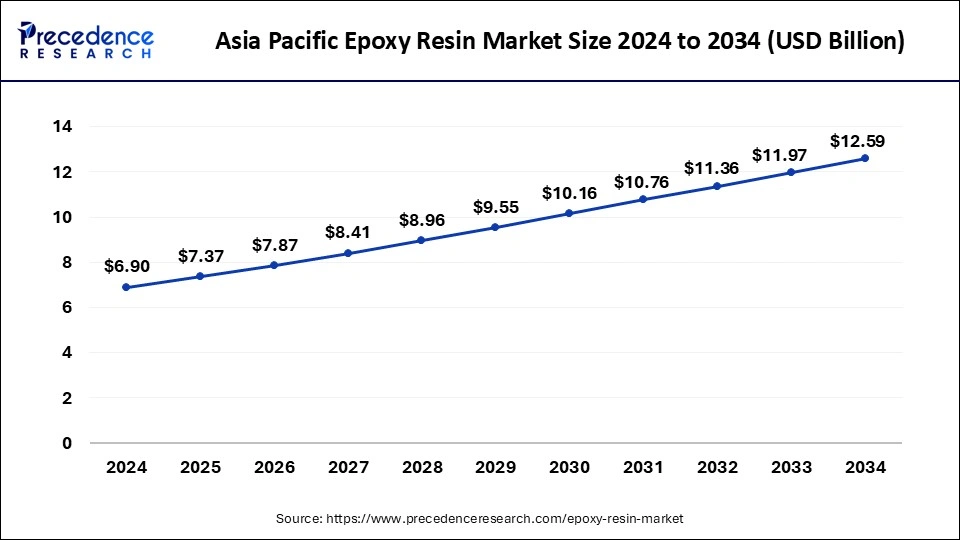

How Big is the Asia Pacific Epoxy Resin Market?

According to Precedence Research, the Asia Pacific epoxy resin market size is expected to reach USD 7.87 billion in 2025. It is expected to be worth around USD 12.59 billion by 2034, growing at a CAGR of 6.13% from 2025 to 2034.

How Asia Pacific Dominated the Epoxy Resin Market?

Asia Pacific dominated the epoxy resin market in 2024, due to a fast rise in construction activities and surging demand for automobiles in emerging markets like India, Japan, and South Korea. The availability of raw materials is high in the region, which lowers the production cost and increases the consumption of the products made of epoxy resin in diverse end-use industries.

China dominated the market, which was facilitated by mega-scale infrastructure projects, increasing manufacturing capacity, and the government followed its efforts to preserve economic growth.

Your Detailed Market Analysis Awaits – Request Sample Pages Now ➡️ https://www.precedenceresearch.com/sample/2150

India Epoxy Resin Market Expansion

- Booming Construction & Real Estate: Rapid urbanization and smart city initiatives increasing demand for epoxy flooring, adhesives, and protective coatings.

- Automotive Production Growth: Rising vehicle production and focus on lightweight, durable materials fueling epoxy use in structural and coating applications.

- Electrical & Electronics Manufacturing Push: Government initiatives like Make in India and PLI schemes encouraging local production of electronics—driving demand for epoxy in PCBs and encapsulation.

- Shift Toward Renewable Energy: Expansion of solar and wind energy infrastructure supporting epoxy resin usage in protective and structural applications.

Why is Europe the Fastest-Growing in the Epoxy resin market?

Europe experiences the fastest growth in the market during the forecast period. Demands in the areas of paints & coatings, construction, wind turbines, and electrical and electronics are booming. Germany was the leader of the market, as it was the European center of automotive manufacturing and the leader in industrial innovation.

The automotive industry in the country is expected to increase the use of high-performance coatings and composite materials. Moreover, Europe is devoted to the use of renewable energy, particularly offshore and onshore wind energy plants, which are boosting the application of epoxy resins in the construction of turbine blades.

Germany Epoxy Resin Market Expansion

- Strong Demand from Aerospace & Defence: Increased use of epoxy composites in lightweight aircraft components and defence applications.

- Growth in Wind Energy Sector: High use of epoxy resin in wind turbine blades driven by clean energy policies and large-scale wind projects.

- Infrastructure Revamp Projects: Government-funded modernization of bridges, highways, and buildings is boosting demand for epoxy coatings and adhesives.

- Advanced Manufacturing & R&D: Presence of leading chemical manufacturers and investment in high-performance formulations for electronics and automotive sectors.

-

Packaging & Industrial Coatings Boom: Growth in packaging and corrosion-resistant coatings, especially in industrial and marine environments.

Epoxy Resin Market Segmentation Analysis

Application Analysis

The paints and coatings segment dominated the market in 2024 since it is used in residential, commercial, industrial, automotive, marine, and infrastructure applications. They are desirable in projects that need durability and environmental compliance due to their better adhesion and outstanding anticorrosive properties, and low volatile organic compounds.

Coatings are applied widely all over the building interiors and exteriors, on industrial equipment, within hulls of ships, or on wastewater treatment plants and automotive bodies.

The electrical & electronics segment is the fastest-growing in the market during the forecast period, motivated by the growing need to insulate, encapsulate, and protect sensitive parts. Epoxy resins are the ultimate electrical insulators, have very high tensile and flexural values, and do not readily absorb moisture, chemicals, or heat degrade, so they are vital to printed circuit boards (PCBs), transformers, insulators, semiconductors, and LEDs.

Also, the advancement of miniaturization of electronic parts and the increased energy-saving demands call for materials with enhanced bonding capacity, protective properties, and hence, increase the use of epoxy resin.

Raw Material Analysis:

The DGBEA (Bisphenol A and ECH) segment held the largest share in the epoxy resin market in 2024. It is highly versatile and performs well with the best adaptability in a broad spectrum of various applications. DGBT epoxy resins are recognised to be high mechanical strength, strong adhesion, resistant to chemical corrosion and abrasion, and durable, which makes them a necessary material in an array of industries, including construction, automotive, electronics, aerospace, and protective coatings.

In addition, the wide applicability of DGBEA resins to different curing agents and additives makes them widely applicable in different environments.

Technology Analysis:

The solvent-cut epoxy segment dominated the epoxy resin market in 2024, due to the improvement in the advantages of workability and processing. Solvents added to epoxy formulation enhance flow, wetting, and penetration into the substrate, thus having good-looking surface coverage, excellent adhesion, and quality finishing.

Such characteristics render solvent-cut epoxies popular in applications where precision and high bonding strength are needed, where they take on the forms of coatings and adhesives, and in industrial maintenance. The competitors have enhanced the power of the segment through their capacity to provide high-quality finishes, uniform performance, and efficiency of production.

Sales Channel Analysis:

The direct company sale segment held the largest share in the epoxy resin market in 2024 because it offered its customers tailored services and established good customer relationships. This will enable the manufacturers to interact with the end users and have a better knowledge of customer needs, project requirements, and expected desired performance. They will be able to provide custom-tailored epoxy resin formulations as well as technical support and assistance.

The practice also allows the maintenance of uniform product quality, authenticity, and compliance with the standards used in the industry since products are delivered directly by the manufacturer, by-passing intermediaries.

End Use Analysis:

The consumer goods (including sporting equipment) segment dominated the market in 2024. Epoxy resins find extensive application in the production of adhesives/sealants used in bonding and sealing various products, e.g., electronics, home, furniture, and automotives. Moreover, epoxy resins are a fundamental constituent in ultra-competent compositions that are applied to aerospace components, play gear, like skis, snowboards, bikes, and recreational goods.

Consumption of the epoxy resin has been spurred by the rising demand for consumer goods that are light and durable, as well as the rising use of superior materials in sporting and lifestyle products.

✚ Related Topics You May Find Useful:

➢ Resin Market: Understand the evolving role of polymers in manufacturing, packaging, and construction

➢ Specialty Resins Market: See where high-performance polymers are enabling advanced industrial applications

➢ Coating Resins Market: Discover innovations driving durable and sustainable protective finishes

➢ Polyurethane Resin Market: Learn how versatility is fueling adoption across coatings, adhesives, and sealants

➢ Plastic Resins Market: Track trends shaping global plastics production, sustainability, and recycling

➢ Low Temperature Powder Coatings Market: Explore energy-efficient coating solutions for heat-sensitive applications

➢ Protective Coatings Market: See how performance and sustainability are redefining industrial surface protection

➢ Rosin Resin Market: Analyze rising demand in adhesives, inks, and road-marking applications

➢ Lignin-Based Resins Market: Gain insight into bio-based resin innovation for a circular economy

➢ High Performance Composites Market: Discover the materials enabling aerospace, defense, and renewable energy

➢ Powder Coating Market: Understand how durability and low-VOC technology are driving adoption

➢ Aerospace Adhesives and Sealants Market: Explore the specialized bonding solutions ensuring flight safety

➢ Electronic Adhesives Market: Learn how bonding solutions are powering miniaturization and high-performance electronics

➢ Conformal Coatings Market: See how protective coatings safeguard electronics in harsh environments

Top Players in the Epoxy Resin Market

- 3M

- Aditya Birla Management Corp. Pvt. Ltd.

- Atul Ltd

- BASF SE

- Solvay

- Huntsman International LLC

- Kukdo Chemical Co., Ltd.

- Olin Corp.

- Sika AG

- Nan Ya Plastics Corp.

- Jiangsu Sanmu Group Co., Ltd.

- Jubail Chemical Industries LLC

- China Petrochemical & Chemical Corp. (SINOPEC)

- Hexion

- Kolon Industries, Inc.

- Techstorm

- NAGASE & Co., Ltd.

Recent Developments:

- In March 2025, BASF and Sika researched together a new amine building block to cure epoxy resin named Baxxodur 151 EC. Specifically formulated as an industrial and commercial flooring, it had low viscosity and good flow that improved its effectiveness in manufacturing plants, warehouses, assembly, and parking facilities.

- In February 2025, Superior Materials will take over the distribution of Westlake Epoxy in, Northeast, Mid-Atlantic, and Southeast United States. Commencing February 1, it is distributing EPON resins, EPI-REZ water-based resins, EPIKURE curing agents, and HELOXY functional modifiers, and extends the product line of Westlake epoxy in the area and enhances the specialty chemicals portfolio of Superior Materials.

-

In February 2025, the Asahi Kasei board agreed to an absorption by merger into a wholly-owned subsidiary of Asahi Kasei, Asahi Kasei Epoxy Corporation. The changes were an attempt to make the operations lean and increase efficiency, and the formal merger will occur on April 1, 2026, where epoxy operations will merge into the mother company.

Epoxy Resin Market Segments Covered in the Report

By Raw Material

- DGBEA (Bisphenol A and ECH)

- DGBEF (Bisphenol F and ECH)

- Novolac (Formaldehyde and Phenols)

- Aliphatic (Aliphatic Alcohols)

- Glycidylamine (Aromatic Amines and ECH)

- Other

By Application

- Paint & Coatings

- Construction

- Electrical & Electronics

- Wind Turbine & Composites

- Civil Engineering

- Adhesive & Sealants

- Others

By Technology

- Solvent Cut Epoxy

- Liquid Epoxy

- Waterborne Epoxy

- Others

By Sales Channel

- Direct Company Sale

- Direct Import

- Distributors & Traders

- Retailers

By End User

- Building & construction

- Automotive, large & heavy vehicles & railroads

- Aerospace

- Consumer goods (including sporting equipment)

- General industrial

- Wind power

- Marine

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

Thank you for reading. You can also get individual chapter-wise sections or region-wise report versions, such as North America, Europe, or Asia Pacific.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.precedenceresearch.com/checkout/2150

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 804 441 9344

Stay Ahead with Precedence Research Subscriptions

Unlock exclusive access to powerful market intelligence, real-time data, and forward-looking insights, tailored to your business. From trend tracking to competitive analysis, our subscription plans keep you informed, agile, and ahead of the curve.

Browse Our Subscription Plans@ https://www.precedenceresearch.com/get-a-subscription

About Us

Precedence Research is a worldwide market research and consulting organization. We give an unmatched nature of offering to our customers present all around the globe across industry verticals. Precedence Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semi-conductors, chemicals, automotive, and aerospace & defense, among different ventures present globally.

Web: https://www.precedenceresearch.com

Our Trusted Data Partners:

Towards Healthcare | Towards Packaging | Towards Automotive | Towards Chem and Materials | Towards FnB | Towards Consumer Goods | Statifacts | Towards EV Solutions | Towards Dental | Nova One Advisor | Market Stats Insight

Get Recent News:

https://www.precedenceresearch.com/news

For the Latest Update Follow Us:

LinkedIn | Medium | Facebook | Twitter

✚ Explore More Market Intelligence from Precedence Research:

➢ Aerospace Adhesives and Sealants Market: Explore how advanced bonding solutions are supporting next-gen aircraft manufacturing

➢ Moisture Curing Adhesive Market: See why durable, weather-resistant bonding is gaining ground in construction and automotive

➢ Building and Construction Sealants Market: Understand the role of high-performance sealing in sustainable infrastructure

➢ Composite Adhesive Market: Discover how lightweight bonding is reshaping aerospace, automotive, and marine industries

➢ Automotive Adhesive Tapes Market: Track innovations driving safer, lighter, and more efficient vehicle assembly

➢ Self-Adhesive Labels Market: See how branding and smart labeling trends are fueling demand across industries

➢ Single Coated Adhesive Tapes Market: Analyze the growing use in packaging, electronics, and medical applications

➢ Flooring Adhesive Market: Learn why flexible and eco-friendly adhesives are in demand for modern interiors

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.